When you’re looking into replacing sheetrock, start by evaluating any visible damage like cracks or water stains, and use a utility knife to uncover any hidden issues. You’ll need tools such as a drywall saw, T-square, joint tape, and a variety of drywall knives. Don’t forget to wear safety gear, including dust masks and goggles, to protect yourself during the process. Install the new sheetrock with precise cuts and secure it with screws, then apply joint compound and sand for a smooth finish. If you’re curious about how to achieve a seamless paint job and organize your workspace post-project, there’s more useful advice to discover.

- Assessing Sheetrock Damage

- Required Tools and Materials

- Safety Precautions Overview

- Preparing the Work Area

- Removing Damaged Sheetrock

- Measuring and Cutting New Drywall

- Securing Drywall to Studs

- Taping Drywall Seams

- Applying Joint Compound

- Sanding for Smoothness

- Priming the Drywall Surface

- Painting for a Seamless Finish

- Cleaning Up the Worksite

- Tips for Professional Results

- Frequently Asked Questions

- Conclusion

Assessing Sheetrock Damage

Identifying sheetrock damage is your first step before making any repairs. Start by looking for obvious signs like cracks, holes, and water stains. These can tell you a lot about the severity and the kind of repair needed.

When you’re evaluating sheetrock damage, don’t just eyeball the surface. Use a utility knife to gently probe any suspicious areas. This helps you find hidden damage that could compromise the structure around it.

If you discover a small area, under 8 square feet, that’s damaged, you might get away with a simple fix. But if the damage is extensive, or the material feels soft and spongy, you’ll likely need to replace drywall to guarantee stability and avoid issues like mold.

Also, consider the age and type of your sheetrock. Older materials or those not up to current standards might require complete replacement for safety reasons.

When you’re ready to patch or replace, check if there’s any need to patch a stud that has a cutout. This step is essential for maintaining the integrity of your wall’s framework before you proceed with hanging new sheetrock.

Required Tools and Materials

To successfully replace sheetrock, you’ll need several key tools and materials. First off, you’re going to need a utility knife and a drywall saw for cutting the old material and shaping the new pieces. A T-square will guarantee your cuts are straight and precise.

When it comes to replacing all drywall in a house or just a section, having the right type of drywall is essential. Choose from standard, moisture-resistant, or fire-rated, depending on the room’s requirements.

For attaching the drywall to the frame, you’ll need fasteners. Typically, 1 1/4-inch screws or nails are used to secure the panels in place. To achieve a seamless finish when changing drywall, you’ll also require drywall knives and joint tape to cover the seams between panels.

Lastly, the finishing touches are key. You’ll need a joint compound to fill in the seams and sandpaper to smooth everything out before you paint.

These materials are vital in guaranteeing your new walls aren’t only sturdy but also pleasing to the eye. So, whether you’re tackling a small patch job or replacing sheetrock walls throughout your home, having these tools and materials will get the job done right.

Safety Precautions Overview

Before you start replacing sheetrock, it’s essential you’re equipped with the right protective gear. Make certain your workspace is free of hazards to manage any risks effectively. These precautions help prevent injuries and create a safer environment for your project.

Protective Gear Essentials

Wearing the right protective gear is essential when replacing sheetrock to guarantee your safety throughout the process.

First and foremost, you’ll need to don a dust mask or respirator. This is vital to protect your lungs from the fine drywall dust and potential allergens that fill the air during the installation and sanding phases. Don’t take any chances with your respiratory health.

Next, make sure to wear safety goggles. These aren’t just helpful; they’re a must to shield your eyes from flying debris and dust, particularly when you’re cutting or sanding the drywall. Remember, regular eyeglasses won’t provide adequate protection here, so opt for proper safety goggles.

You’ll also want to wear gloves to protect your hands from the sharp edges of the drywall sheets and from skin irritation caused by joint compounds and other materials. Choose gloves that are durable yet allow enough dexterity to handle tools and materials effectively.

Lastly, it’s wise to wear protective clothing such as long sleeves and durable pants. These can help prevent cuts and abrasions from the rough, sometimes sharp, edges of sheetrock.

This kind of attire also shields your skin from potential irritants. Make sure your workspace has adequate ventilation to further minimize risks.

Workspace Hazard Management

Managing workspace hazards effectively guarantees a safer environment for replacing sheetrock. Before you start, confirm your workspace is clear of furniture and other obstacles. This not only creates more room for maneuvering but also notably lowers the risk of accidents as you move tools and materials around.

Always wear the right personal protective equipment (PPE). Gloves, goggles, and dust masks are your first line of defense against the dust and debris you’ll encounter during the job. They prevent minor injuries and protect you from long-term health issues related to dust inhalation.

Don’t forget to lay down drop cloths or poly sheeting. This step is important to protect your floors and surrounding areas from the mess created during the cutting and installation of sheetrock. It makes cleanup easier and prevents damage to existing surfaces.

Regularly check your tools before use. Confirming they’re in good working condition is essential; malfunctioning equipment can’t only slow you down but also pose serious safety risks.

Lastly, keep a first aid kit within easy reach. It’s critical for addressing any minor injuries quickly, helping you to safely continue your work without unnecessary delays.

Preparing the Work Area

To guarantee a smooth and safe process when replacing sheetrock, start by clearing the area of any furniture and obstacles. You’ll need ample space to maneuver and make sure nothing gets damaged during the process.

Here’s how you can effectively prepare your workspace:

- Remove Furniture and Obstacles: Shift all furniture and any other obstacles out of the room. If an item is too heavy to move, cover it securely with a drop cloth or plastic sheeting.

- Protect Floors and Immovable Objects: Lay down drop cloths or plastic sheeting over the flooring and any fixtures that can’t be removed. This step is essential to prevent damage from dust and debris.

- Locate and Mark Wall Studs: Use a stud finder to locate the studs behind the existing drywall. Mark these locations clearly with a pencil. This will make it easier to secure the new sheetrock properly.

- Measure the Area: Accurately measure the area where the new drywall will be installed. Knowing the exact dimensions helps in purchasing the right amount of materials, avoiding unnecessary waste and additional trips to the store.

Don’t forget to wear your safety gear—gloves, goggles, and a dust mask are vital to keep you protected.

Removing Damaged Sheetrock

When you’re ready to tackle removing damaged sheetrock, it’s vital to first assess the extent of the damage thoroughly.

You’ll need to use safe removal techniques to guarantee you don’t cause further harm to the surrounding areas.

Cut carefully around the damage, then gently pull out the affected sheetrock, checking for any hidden issues behind it.

Identify Damage Extent

Before you begin replacing damaged sheetrock, it’s vital to assess the extent of the damage. This initial step will guide you in how much material needs to be removed and replaced, guaranteeing that you address all areas that could compromise the integrity of your wall or ceiling.

To effectively evaluate the damage, follow these steps:

- Inspect for Visible Signs: Look for water stains, cracks, or holes. These indicators help determine whether the damage is merely superficial or if it has affected the structural integrity.

- Cut Away Loose Material: Use a utility knife to remove any damaged sheetrock. This allows you to see if there’s mold or further deterioration underneath that needs attention.

- Measure the Affected Area: Accurately measure and mark a clean square or rectangle around the damaged section. This guarantees you’ll only remove what’s necessary, making the repair process more straightforward.

- Check for Moisture: If there’s water damage, investigate for any leaks or sources of moisture. Addressing these issues now can prevent future damage and save you from repeated repairs.

Safe Removal Techniques

Clearing your workspace and laying down drop cloths will greatly reduce the mess as you begin removing damaged sheetrock.

First, you’ll need to pinpoint and mark the damaged area. Use a utility knife or drywall saw to outline a square or rectangular section around the damage. This will help you achieve cleaner edges and make the repair work look more professional.

Next, grab an oscillating multi-tool or jab saw to cut through the marked sheetrock. Be extra careful during this step; you don’t want to accidentally hit any hidden pipes or wiring.

Once you’ve cut around the marked area, gently remove the damaged piece. Take this opportunity to inspect the framing and surrounding areas for further damage or signs of mold. It’s essential to address these issues before you install new sheetrock.

Finally, dispose of the old sheetrock responsibly. Check your local waste management regulations to confirm you’re getting rid of the material correctly, especially if it’s contaminated with mold or other hazards.

Taking these steps not only keeps your workspace clean but also prepares it for a successful sheetrock replacement.

Measuring and Cutting New Drywall

To guarantee a perfect fit for your new drywall, start by accurately measuring the height and width of the space where it will be installed. Remember to subtract 1/8 inch from each dimension to make certain the drywall fits snugly without being overly tight, which can cause it to crack.

Here’s a straightforward list to guide you through the cutting process:

- Measure Precisely: Use a tape measure to find the exact dimensions of the area needing drywall. Subtract 1/8 inch from both the height and width to allow for a slight gap that aids in installation.

- Mark the Drywall: Lay the drywall sheet on a flat surface. Use a T-square to draw straight lines where you’ll make your cuts. This tool helps keep your lines true, making certain the finished edges are clean and fit well.

- Score and Snap: With a utility knife, score deeply along the marked lines. Then, gently snap the drywall along these scored lines. Flip the sheet over and slice through the backing paper to complete your cuts.

- Handle Intricate Cuts: If your installation includes any unusual shapes or obstacles, use a drywall saw. This tool is especially handy for making precise cuts or adjustments.

Always wear safety goggles and a dust mask to protect yourself from debris while cutting.

Securing Drywall to Studs

After measuring, marking, and cutting your new drywall, it’s time to attach it securely to the wall studs. You’ll need 1 1/4 inch drywall screws, placing them about every 12 to 16 inches along the edges and every 16 inches in the field of the sheet.

It’s essential that the screw heads are sunk just below the surface of the drywall. This guarantees a smooth finish when you’re mudding, avoiding any unsightly bumps.

When hanging vertical sheets, make sure the edges align with the center of the studs. This alignment helps maintain the structural integrity of the wall and prevents the drywall from sagging over time.

For corners, you should use a corner bead. This reinforces the edges, and you’ll secure it with screws to the underlying studs to enhance strength.

Before you start, always use a stud finder to check the placement of studs. This step guarantees your drywall is securely attached and helps avoid any potential issues down the line.

Taping Drywall Seams

Once you’ve secured the drywall to the studs, it’s time to focus on taping the seams to guarantee a smooth, seamless finish. Here’s how you’ll tackle this fundamental step:

1. Choose the Right Tape: Opt for fiber mesh tape. It’s strong and perfect for areas prone to cracking. This type of tape sticks well with joint compound and boosts the overall durability of your work.

2. Apply the Tape: Firmly press the tape along the drywall seams. Make sure it’s perfectly aligned and smooth out any bubbles or wrinkles. This initial application is critical for a solid base.

3. First Layer of Joint Compound: With a 10 or 12-inch knife, apply a thin coat of joint compound over the tape. Your goal here is to fill any gaps and feather the edges to blend seamlessly into the existing drywall.

Remember, you’re not looking to build too much thickness at this stage.

4. Maintain Evenness: As you apply the compound, maintain a light touch. Avoid pressing too hard, which can create uneven surfaces.

This is about creating a smooth, flat surface that will hide the tape entirely once everything is finished and painted.

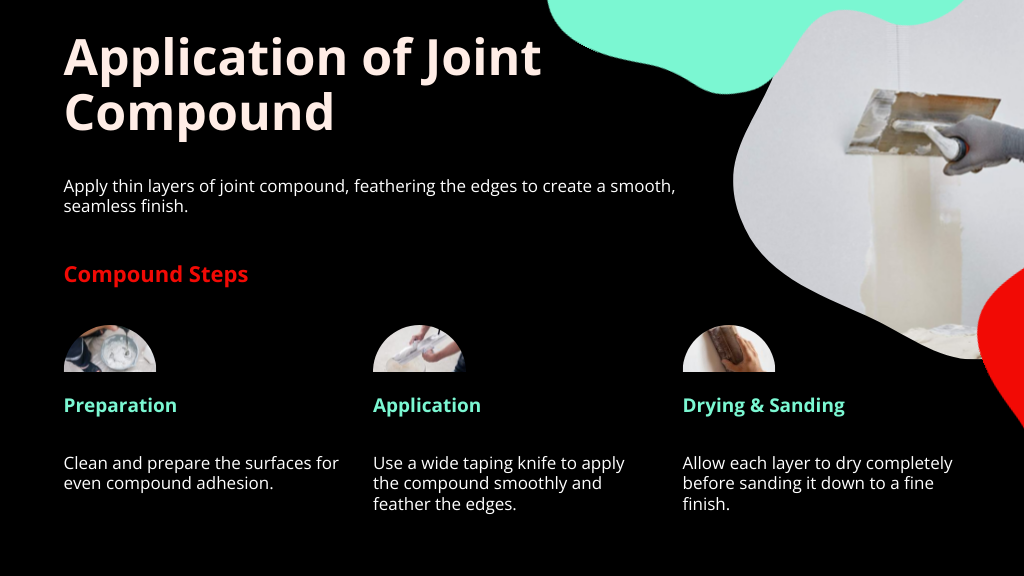

Applying Joint Compound

Before you start applying joint compound, make certain the surfaces are clean and free from any dust or debris to guarantee the mud adheres properly.

Use a wide taping knife to apply the compound smoothly, feathering out the edges to avoid visible lines and bumps.

Let each layer dry thoroughly before sanding it down to a fine finish, checking for smoothness before adding another coat.

Preparing Surfaces for Application

To guarantee your sheetrock installation looks seamless, start by evenly spreading joint compound over the seams and patched areas using a putty knife. This is the first step to creating a smooth and professional finish on your walls.

Here’s how you can effectively prepare your surfaces for the application of joint compound:

- Spread Evenly: Use a broad putty knife to apply the joint compound across all seams and patches. Ascertain that the layer is even to avoid raised lines or bumps.

- Feather the Edges: Gradually taper the edges of the joint compound into the existing wall. This feathering technique helps to blend the compound seamlessly, reducing the visibility of joints.

- Allow Drying Time: Patience is key — allow the compound to dry completely, usually about 24 hours, before adding another layer. Rushing this can lead to imperfections.

- Sand Smoothly: Once the final layer is dry, lightly sand the area with 120 to 150-grit sandpaper. This smooths out any minor imperfections and prepares the surface for priming and painting.

Techniques for Smooth Application

After allowing the joint compound to dry as outlined in surface preparation, it’s time to focus on mastering the application techniques to secure your sheetrock looks impeccable.

Start by grabbing your putty knife and applying a thin layer of joint compound over the patched area. You’ll want to aim for a feathered edge, which guarantees a seamless blend with the existing drywall.

For the best finish, you should apply multiple thin coats. Each layer needs to be completely dry before you add the next. This strategy prevents the compound from becoming too thick or uneven, which can lead to issues later on.

When you’re applying the joint compound, make sure to extend your coverage. For the initial coat, go about 2-3 inches beyond the edges of your patch. This helps in hiding any seams.

With each subsequent coat, increase your reach by up to 6-12 inches. This expansion makes the patch less noticeable and integrates it smoothly with the surrounding area.

Lastly, always clean your tools between applications. Removing any dried compound from your knife ensures that each layer is as smooth as possible, setting you up for success in the final finishing steps.

Drying and Sanding Tips

Once you’ve applied the joint compound in thin layers and allowed each to dry thoroughly—typically over a 24-hour period—it’s time to focus on sanding. This phase is essential for achieving a smooth, seamless finish on your walls.

Here’s how you can effectively sand the joint compound:

- Choose the Right Sandpaper: Start with 120 to 150-grit sandpaper. This grit size is ideal for achieving a smooth finish without damaging the underlying drywall.

- Feather the Edges: As you sand, feather the edges of the joint compound beyond the boundaries of the previous coat. This technique helps create a smooth shift between the compound and the existing wall surface.

- Keep It Clean: Regularly clean your sanding tools and the area around your work. This minimizes dust, which can obscure your view of imperfections and affect the final finish.

- Opt for a Damp Sponge: For areas where traditional sanding is challenging or to reduce dust, lightly sand the joint compound with a damp sponge. This method also helps achieve an exceptionally smooth finish.

Sanding for Smoothness

Why is achieving a smooth finish on your sheetrock so important? Well, it’s not just about aesthetics. A smooth surface guarantees that subsequent layers of paint or wallpaper adhere properly and look flawless.

Here’s how you’ll get there: start by selecting the right sandpaper, typically between 120 to 150-grit. This range helps smooth out the joint compound evenly after it’s fully dried.

You’ll need to sand lightly to avoid gouging the drywall. Always use a circular motion; it helps achieve a more uniform finish. Remember, this isn’t a race. Take your time to get it right.

It’s vital to protect yourself during this process. Always wear a dust mask and goggles to shield yourself from the fine dust and debris. This dust isn’t just messy—it can be hazardous to your health.

After sanding, take a damp rag or sponge and gently wipe down the surface. This step removes any lingering dust particles, guaranteeing a clean area for your next application, whether that’s more joint compound or eventually, paint.

Depending on the initial condition, you might find yourself sanding multiple times. Each session should move you closer to that seamless look, with the final pass using the finest grit you’ve got.

Priming the Drywall Surface

Before you apply your chosen paint, priming the drywall is vital to confirm an even and durable finish. Priming isn’t just an optional step; it’s a pivotal part of making sure your paint job looks great and lasts. Here’s what you need to do:

- Choose the Right Primer: Opt for an acrylic or latex-based primer designed specifically for drywall. These types provide the best coverage and durability, setting the stage for your topcoat.

- Apply One Coat for Most Surfaces: In general, a single coat of primer is enough. Use a roller for larger areas and a brush for corners and edges to guarantee even coverage.

- Address Heavily Textured or Repaired Areas: If you’re dealing with surfaces that are heavily textured or have undergone significant repairs, consider applying a second coat of primer. This helps to achieve a uniform base across all areas.

- Allow Proper Drying Time: Follow the manufacturer’s instructions for drying time, typically between 1 to 3 hours. Confirm the primer is completely dry before moving on to painting; this prevents any issues with adhesion or texture.

Painting for a Seamless Finish

Having applied a thorough coat of primer, you’re set to begin painting for that flawless finish. First, confirm the joint compound has dried completely and is sanded smooth. Any imperfections here will show through your paint, so take your time to get a smooth base.

Choose a paint that matches the sheen of your existing walls. Whether it’s matte, eggshell, or satin, matching the sheen plays an essential role in achieving a seamless look.

Start with thin, even coats of paint, which help prevent drips and streaks. Allow each coat to dry thoroughly before applying the next one. This patience pays off with a professional-looking finish.

If your wall has a texture, now’s the time to replicate it. You can use texture spray or a stippling technique to match the surrounding areas. This step is critical for blending the new section with the old, guaranteeing the repair is invisible once you’re done.

Cleaning Up the Worksite

After replacing the sheetrock, it’s important to clear away all debris to keep your workspace clean and safe. Tidying up not only prevents accidents but also sets you up for any next steps without clutter.

Here’s how you can effectively clean your worksite:

- Vacuum with a HEPA Filter: Start by using a vacuum equipped with a HEPA filter to suck up all the fine dust particles. This type of vacuum is vital because it traps smaller particles that other vacuums might recirculate back into the air.

- Wipe Down Surfaces: Once the bulk of the dust is vacuumed, grab a damp sponge or cloth and gently wipe down all surfaces. This removes any lingering dust and prevents it from spreading around your home or settling back on your new sheetrock.

- Dispose of Waste Properly: Gather all the waste materials, including old drywall pieces, used screws, and empty joint compound containers. Make sure to dispose of them according to your local regulations, which might involve recycling some materials.

- Store Tools and Materials: Finally, organize and store all your tools and leftover materials. This keeps your workspace tidy and guarantees everything is handy for your next project.

Tips for Professional Results

Now that your worksite is clean and organized, focus on achieving professional results as you install the new sheetrock. First, select the right type of drywall. In areas like bathrooms or kitchens, you’ll want to use moisture-resistant drywall, and in garages or around furnaces, opt for fire-rated drywall. This guarantees both durability and safety.

When hanging your drywall, make sure to stagger the seams. This technique not only enhances the wall’s structural integrity but also minimizes the risk of future cracking. Properly tape these seams with joint tape to fortify the connections.

For a truly smooth finish, apply at least two to three thin layers of joint compound over the taped seams, allowing each layer to fully dry before applying the next. Sand between each application to eliminate any lumps or ridges. If you’re pressed for time, consider using a quick-setting joint compound. It dries faster and still provides a strong bond.

Lastly, invest in high-quality tools. A sharp drywall knife and a reliable T-square are indispensable for making precise cuts, helping you achieve a clean, professional look.

These steps, when executed carefully, will give your sheetrock installation a flawless finish.

Frequently Asked Questions

Can I Replace the Drywall Myself?

You can replace drywall yourself, especially if it’s a small area. You’ll need basic tools and materials. Start with simple fixes to gain confidence before tackling larger sections. It’s cheaper than hiring professionals.

What Is the Average Cost to Replace Drywall?

You’ll find that replacing drywall typically costs between $1.50 and $3.00 per square foot. Factors like labor, location, and material type can affect the final price, so plan your budget accordingly.

Is There a Difference Between Drywall and Sheetrock?

You’re right to ask; while “Sheetrock” is a brand name for drywall, all Sheetrock is drywall but not all drywall is Sheetrock. They refer to similar materials, but Sheetrock is a specific brand.

How to Cut Out Drywall and Replace?

To cut out and replace drywall, you’ll measure and mark the damaged area, use a keyhole saw for removal, and then fit and secure a new piece, finishing with joint compound and sanding.

Conclusion

Now you’re ready to tackle your sheetrock replacement with confidence! Remember, evaluating the damage thoroughly and preparing your workspace carefully sets the foundation for a smooth project. Use the right tools and follow the steps for removal and installation to guarantee a professional finish. Don’t skip the priming and painting for that seamless look. With these tips and a bit of elbow grease, you’ll have walls that are as good as new in no time. Good luck!

Hey there I am so grateful I found your weblog, I really found you by mistake, while I was researching on Yahoo for something else, Anyhow I am here now

and would just like to say thanks a lot for

a incredible post and a all round enjoyable blog (I also love the theme/design),

I don’t have time to read through it all at the moment but I have bookmarked it and also added in your RSS feeds, so

when I have time I will be back to read a lot more, Please do keep up the awesome b.

Some genuinely prize articles on this web site , saved to bookmarks .

I found this similiar one here

Hi i am kavin, its my first occasion to commenting anywhere, when i

read this piece of writing i thought i could also create

comment due to this sensible paragraph.